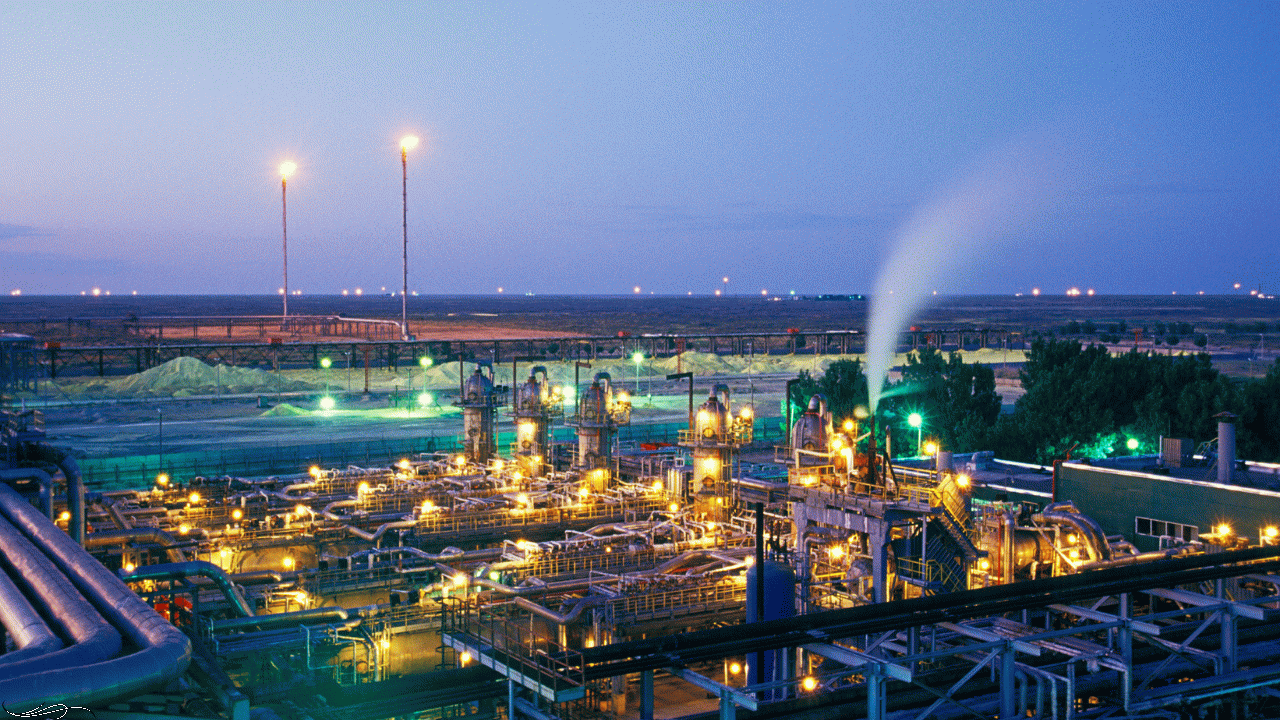

In the ever-evolving oil and gas industry, precision, safety, and efficiency are vital to successful operations. One of the most innovative technologies transforming facility management is laser scanning, a technique that enables accurate, real-time monitoring of complex structures and equipment. This cutting-edge method is redefining how companies assess, maintain, and optimize their assets enhancing both productivity and safety.

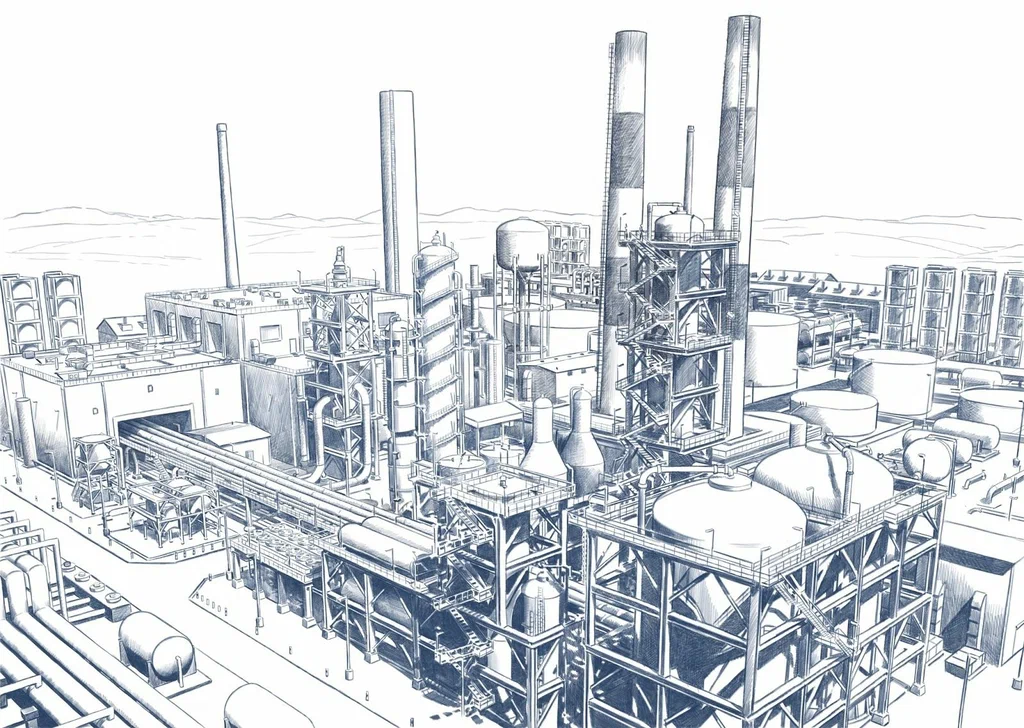

What Is Laser Scanning?

Laser scanning, also known as 3D laser scanning or LiDAR (Light Detection and Ranging), is a technology that captures the exact shape and dimensions of physical objects and environments. By emitting laser beams that measure millions of points per second, it creates highly accurate 3D digital models of facilities, pipelines, and equipment. These models provide detailed insights into structural integrity, spatial relationships, and performance conditions.

Applications in Oil and Gas Facilities

In oil and gas operations where precision is critical laser scanning has a wide range of applications:

- Facility Inspection and Mapping:

Scanning allows for detailed documentation of plants, refineries, and pipelines, producing precise 3D models for engineering and maintenance planning. - Structural Deformation Monitoring:

Laser scanning helps detect structural shifts, corrosion, or misalignment, enabling early intervention before major failures occur. - Asset Management and Maintenance:

The technology supports predictive maintenance, allowing operators to monitor equipment wear and optimize repair schedules. - Design and Retrofit Projects:

When upgrading or expanding facilities, accurate 3D data helps engineers design modifications that integrate seamlessly with existing infrastructure.

Key Benefits of Laser Scanning

- High Accuracy: Provides millimeter-level precision for critical decision-making.

- Enhanced Safety: Minimizes the need for manual inspection in hazardous zones.

- Time and Cost Efficiency: Reduces survey time and prevents costly rework.

- Improved Collaboration: 3D models can be shared across teams, enabling better planning and coordination.

- Comprehensive Documentation: Creates a digital archive for ongoing monitoring and compliance.

Supporting Transparency and Innovation

At the LOGO ORG, we encourage the use of advanced digital tools like laser scanning to promote transparency, innovation, and sustainability in the energy sector. By integrating such technologies, Libya can enhance operational efficiency while ensuring that environmental and safety standards are consistently met.

Conclusion

Laser scanning represents a powerful step forward in the digital transformation of the oil and gas industry. Its ability to deliver accurate, real-time data empowers operators to make informed decisions, optimize performance, and strengthen safety protocols. As the industry embraces innovation, technologies like laser scanning will continue to play a central role in shaping a more efficient and transparent energy future for Libya.