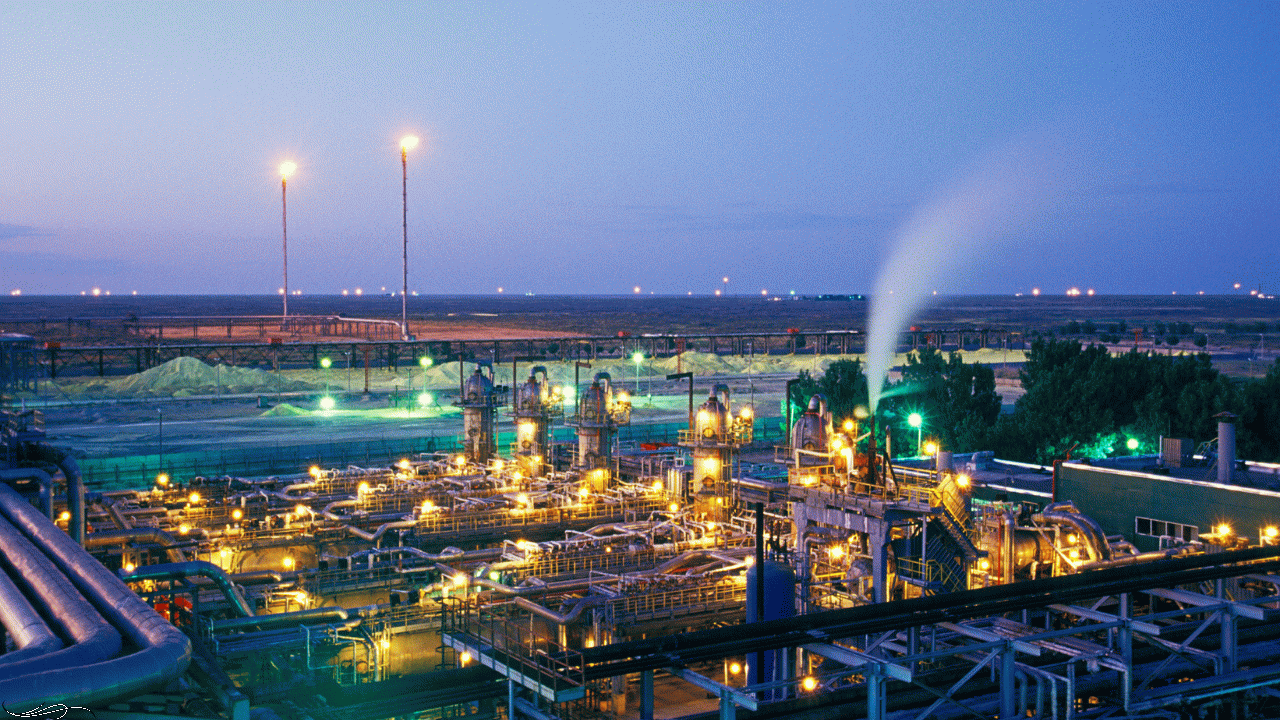

The oil and gas industry is entering a new era of technological innovation one where precision, safety, and efficiency are achieved through advanced digital tools. Among these, laser scanning stands out as a state-of-the-art solution transforming how facilities are monitored, maintained, and developed. Its ability to generate accurate 3D representations of complex environments makes it indispensable for modern energy operations.

Understanding Laser Scanning Technology

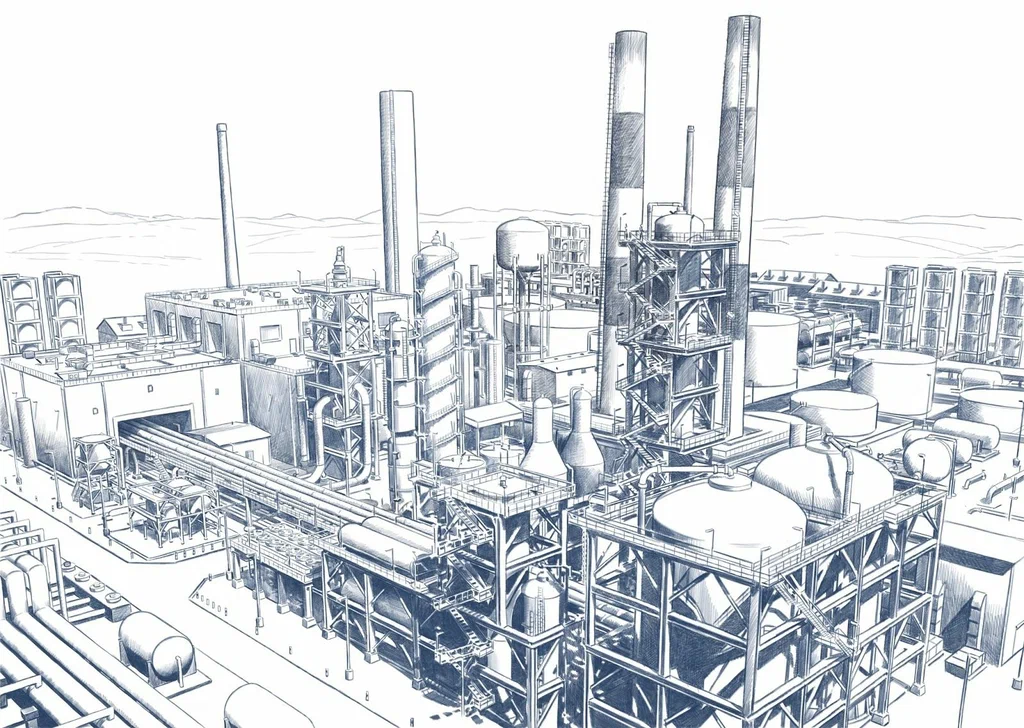

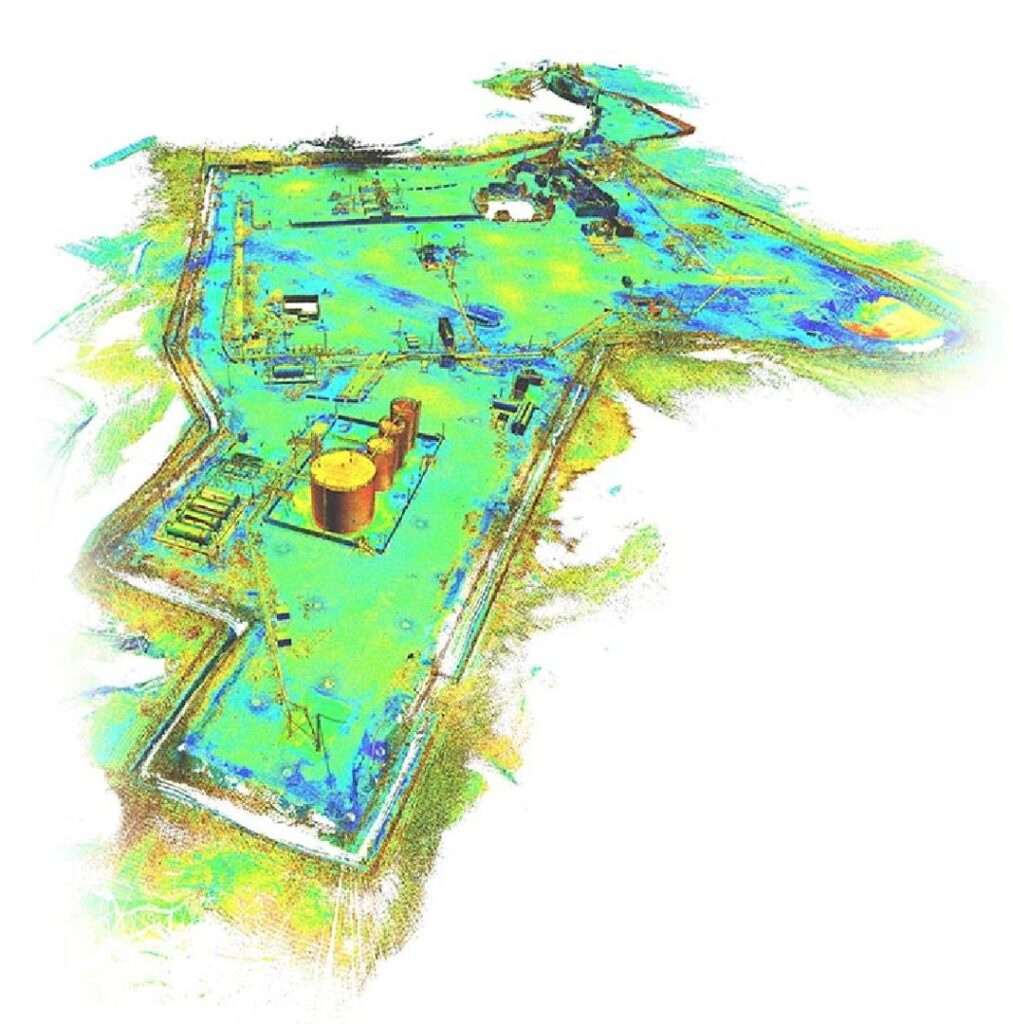

Laser scanning, also known as 3D laser scanning or LiDAR (Light Detection and Ranging), uses laser beams to capture millions of spatial data points in seconds. This information is processed into a detailed 3D digital model of physical assets such as pipelines, refineries, tanks, and offshore platforms. The result is a precise, high-resolution digital twin that engineers and operators can analyze, plan, and use for decision-making.

Applications in the Oil and Gas Sector

Laser scanning is revolutionizing several aspects of the oil and gas industry:

- Facility Design and Modification:

Engineers use 3D models to plan retrofits, expansions, or maintenance work without interrupting ongoing operations. - Structural Integrity Assessment:

The technology enables continuous monitoring of infrastructure to detect corrosion, deformation, or equipment misalignment. - Safety and Compliance:

By reducing the need for manual inspections in hazardous environments, laser scanning enhances worker safety and supports compliance with international safety standards. - Asset Documentation and Management:

Laser-generated models serve as accurate digital records for long-term monitoring, regulatory audits, and lifecycle management.

Advantages of Laser Scanning

- Unmatched Accuracy: Achieves millimeter-level precision for reliable decision-making.

- Time Efficiency: Captures comprehensive data in a fraction of the time required by traditional surveys.

- Enhanced Safety: Minimizes exposure to dangerous field conditions.

- Cost Savings: Reduces errors, rework, and downtime during maintenance or project execution.

- Supports Digital Transformation: Creates a foundation for smart asset management and predictive maintenance.

LOGO ORG’s Commitment to Technological Advancement

At the LOGO ORG, we advocate for the adoption of cutting-edge technologies that promote transparency, efficiency, and sustainability in the energy sector. Laser scanning exemplifies how innovation can drive better management of resources while supporting safer and more accountable industry practices across Libya.

Conclusion

Laser scanning is not just a modern surveying tool—it is a catalyst for transformation in the oil and gas industry. By combining precision, safety, and digital intelligence, it enables smarter decision-making and operational excellence. As Libya continues its journey toward energy modernization, embracing such technologies will be key to achieving long-term sustainability and competitiveness.